The following post ICF Construction – What You Need to Know About an ICF Home Find more on: https://totalsurvival.net

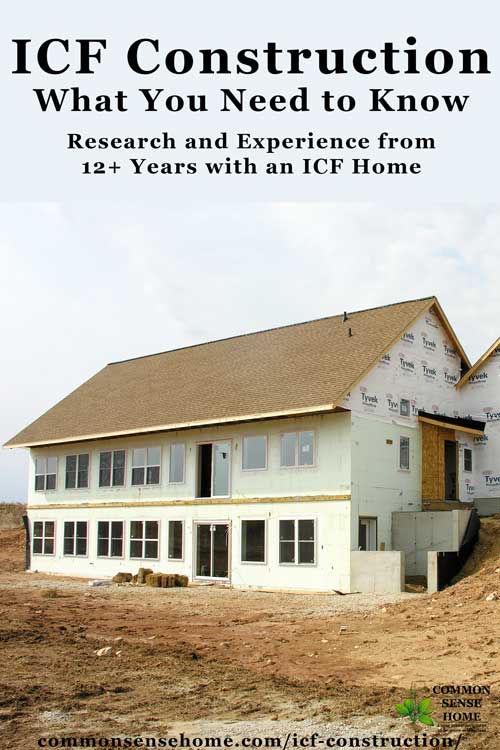

Back when we were researching our “forever home”, we chose ICF construction for a number of reasons. It's tough, energy efficient and should last a lifetime with minimal upkeep. In this post, I'll discuss:

- what ICF construction is

- how it differs from conventional construction

- why we chose Insulated Concrete Forms

- how much energy is saved (for heating and cooling) by using ICF construction

- how an ICF home performs during emergencies

- ICF costs

- whether it's suitable for the do-it-yourselfer

- what it's like living in the house

- recommendations for potential ICF problem areas

Let's get started!

What is ICF (Insulated Concrete Forms)?

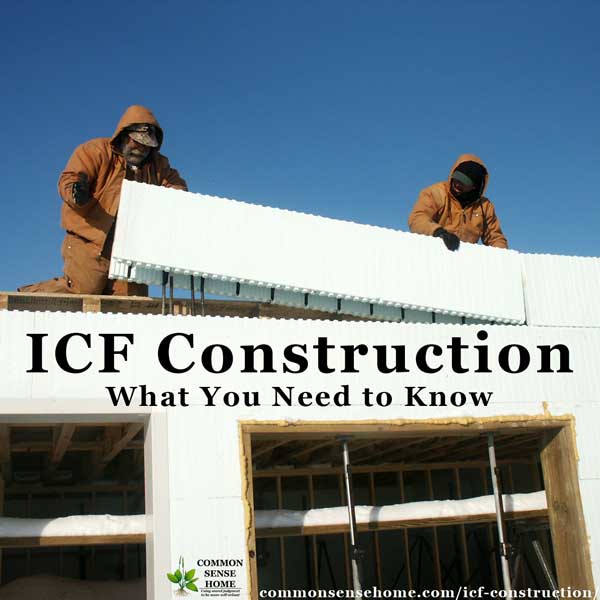

ICF (Insulated Concrete Forms) are premade forms that fit together like legos or large interlocking blocks. The outside of the form is flat sheets of foam insulation. These sheets are connected with plastic framework. During construction, the ICF blocks are fitted together, laced with rebar, and filled with concrete. The forms are insulated on the inside and the outside, providing high level of wall insulation uncommon in standard home construction. Because the ICF blocks fit together virtually seamlessly, there is very little air infiltration, increasing the effective insulation value.

The forms we used to build our house consisted of two layers of insulating foam approximately 2 inches thick, inside and out. The rigid insulation sandwiches a 6 inch thick layer of concrete. The Insulated Concrete Blocks measure roughly 16 inches tall by four feet long by 12 inches wide. They have an inner and outer plastic framework in the forms that stabilizes the form and provides strips that can be drilled into to mount drywall, cabinets, wood trim, and siding on the outside.

ICF can be used for basements, underground homes or entire multi-story homes. They can start at the foundation and go all the way to the roofline, as in our construction. Some builders use only insulated concrete foundation forms and combine them with other building methods above ground.

ICF Energy Efficiency

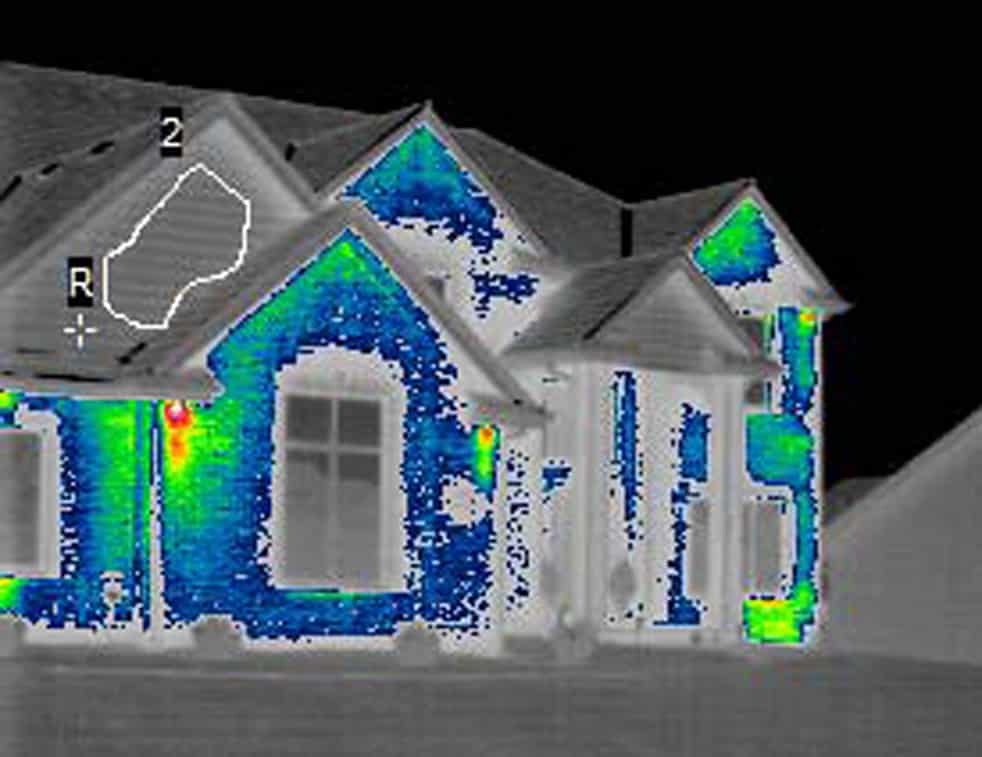

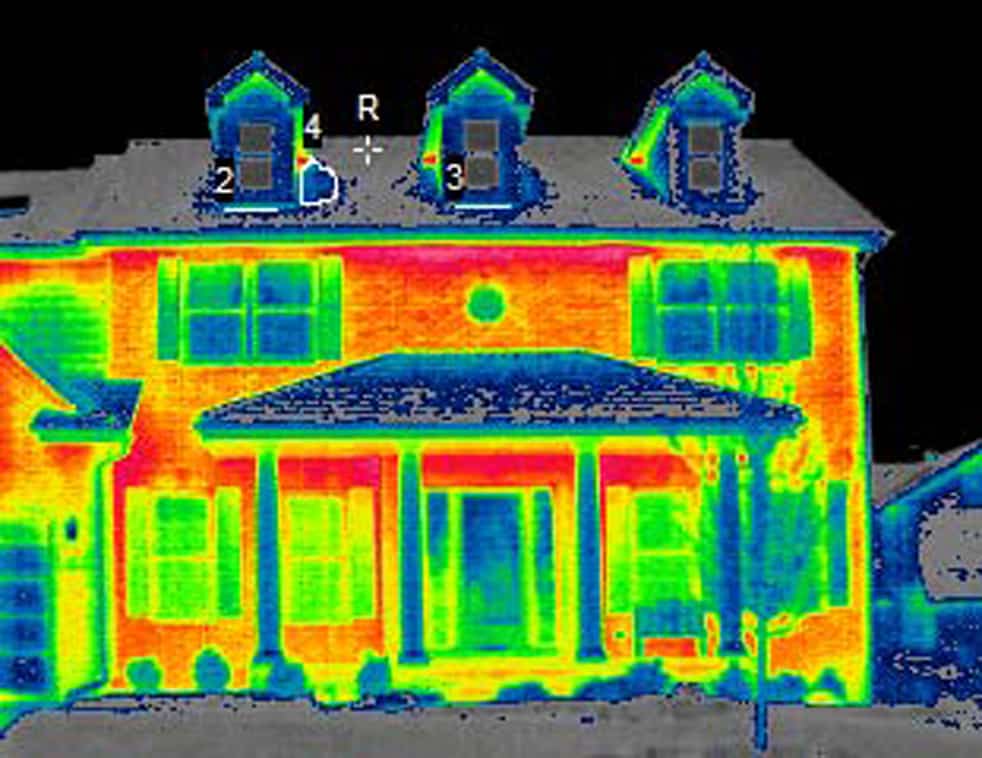

One of the primary reasons we chose Insulated Concrete Form construction was for its energy efficiency. Because the walls are uniformly insulated with a solid sheet of foam inside and out, there are no channels for air to seep through. You will not find hot and cold spots on an ICF wall. In stick built construction, your effective r-value is greatly diminished by air infiltration and heat transfer along wooden studs and around outlets and other wall penetrations where the fiberglass insulation does not fill the area completely (spray foam insulation is better, but you still have heat transfer along the studs).

Infrared Photo of an ICF Home – note the only hot spot (red orange) is where the light is mounted on the front of the home

Infrared photo of stick built (conventional) home – note the bright orange indicating heat loss all over the front of the home

Thermal images courtesy of Reward Wall Systems.

The amount of concrete used in the structure gives the home high thermal mass. This means that is holds temperature very well. Heat it up, and it stays warm – you don’t lose heat to the surroundings. Fill the house with cool night air in the summer and close it up during the day, and it stays cool. Windows at the east and west ends of the home allow us to take advantage of winds off Lake Michigan to flush warm air out of the home.

ConcreteNetwork.com states, “Homes built with ICF walls require about 44% less energy to heat and 32% less energy to cool than a comparable wood-frame house, based on a study of 58 single-family homes located throughout the U.S. and Canada.”

Our Experience with Heating and Cooling

When I ran the numbers on our home, our energy use rates (heating, AC and electricity) placed us in the top 5% of homes in the US is terms of efficiency for square footage. These are my own rough estimates based on utility bills and wood use. My best estimate is that in an average year we get 10% of our heat from passive solar, 40% from wood and 50% from propane via our in floor radiant heating system.

We were able to provide all our hot water and heat over 3000 sq.ft. of living space with a 46 gallon Combi-Cor water heater. (Combi-Cor heater is a water heater with built in heat exchanger for space heating.) In 2013 our Combi-Cor died. We replaced the Combi-Cor water heater with a boiler system because it has a longer estimated lifespan.

Windows are placed to maximize cross ventilation when weather permits. The house is exceptionally airtight, so we also installed a Fantech HRV (Heat Recovery Ventilator). An HRV brings outdoor air inside and preheats it with stale indoor air before it enters the home – fresh air in, stale air out. The HRV could also be fitted with specialized filters to address toxic air problems outside the home. During extremely humid weather, we do have some minor condensation/mildew in the basement if I don’t keep the air moving. In floor radiant heating eliminates this in cooler weather.

ICF Durability

Another reason we chose ICF construction is the durability. When we were building, I read a story about a Florida couple who had built an ICF home for hurricane protection. One night while they were sleeping, they heard a thud outside their bedroom. When they went outside to have a look, they found a truck had run into their home. The truck was a complete loss; the home only had a few hundred dollars of minor damage. With six to eight inches of concrete, most standard ammunition will be stopped. Insulated concrete forms also offer protection from many other concerns, such as:

Storms, Tornadoes and Hurricanes

A quick google search of “ICF hurricane proof” or “ICF tornado resistant” will yield dozens of images of ICF homes left intact in area where the surrounding homes have been leveled. Note: Around 1 am on August 7, 2013, a tornado touched down within 5 miles of our home. Inside our ICF home, the storm sounded very much the same as a typical thunderstorm, although I did note that the thunder had an odd tone to it – that low “freight train” rumble you hear people talk about. The warning sirens never went off, and we stayed in bed. I had no idea there was a tornado nearby until the next day. There was no damage to the house at all, but it's a disconcerting feeling to know that the funnel hit so close without us realizing it. I think the weather radio needs to live in the master bedroom.

Fire

While the contents of the home are still flammable, concrete itself is not. You have no chance of an electrical fire being concealed inside a concrete wall.

Radiation

Concrete can stop all kinds of radiation, including alpha, beta and gamma rays. There’s a reason that nuclear containment vessels are built out of concrete.

Pest Protection

ICF construction is also much more pest resistant – nothing eats or can chew its way in through concrete. (Termites can use the foam for nest material, so in termite prone areas, pre-treated forms should be used.)

Seismic activity

With additional reinforcement appropriate to the level of seismic activity in your area, ICF construction is highly resistant to earthquakes and other shifts.

ICF Cost

At the time that we built, our builder estimated that ICF homes cost about 6% more than stick built. Part of this is the cost of the materials themselves, part of the cost is additional labor involved in working with some aspects of ICF. This is likely to vary over time as material costs fluctuate. Some ICF manufacturers offer discounts on forms to those who are rebuilding homes destroyed by storms in officially declared Federal disaster areas.

As for finding a builder who was familiar with ICF, that was a little tough. At the time that we built, it was a newer technology. Now that its benefits become better known, it’s becoming more widely used, especially in areas that are prone to tornadoes or hurricanes (more on that in a bit). There was no difficulty in obtaining financing or special permitting required, as the use of ICFs is an approved building method.

ICF Construction

As mentioned at the start of the post, the concrete forms are assembled, Lego-style, laced with rebar, and then filled with concrete. Because the concrete and rebar provide the strength of the wall – not the form – temporary framing is used during the pour. Our home uses these forms from the foundation to the roofline. Other options are basement/foundation only, or for building/retrofitting a safe room within the shell of a home.

Looking down into the basement from above. Note the stacks of ICF forms and extensive bracing against the walls.

A wall is framed out with the ICF forms, V-buck openings, and bracing, and then poured in “lifts”. Rebar is set inside the forms and tied. Windows and doors are framed using “bucks” (box outs that create a frame for a window to fit inside.

Here we see the south facing wall of the basement with windows framed and braced.

A “lift” is about three forms high. They fill a wall about three forms high with concrete, let it set, and then fill another three forms in height, and so on. If you attempted to pour the full height of the wall in one pour a blowout would be likely. Because of the need to use lifts, the concrete pumper truck must visit multiple times (once per lift). The multiple concrete pump truck visits are a big part of the cost, along with the rebar labor. (It's a lot tougher to lace rebar through walls than to just lay it in a flat slab.)

Door and window openings in an ICF home under construction. Note blobs of spray foam insulation in bottom of window frames.

Layers are added until a “floor” height is reached and a header/hanger is added to support inside trusses. In the case of the roofline, hurricane ties are added for the roof trusses.

Plumbing and Electrical in ICF Construction

Plumbing and electrical must be done a little differently than with a stick built home. It's much easier to plan any wall perforations in advance than to cut them after the fact. Electrical wiring on exterior walls is done by cutting into the insulation, laying the wire, and then sealing the cut with spray foam insulation and trimming flush. Plumbing on the exterior walls can be done in the same way, but is generally avoided. Inside, the framing, trusses, etc, are the same as in a conventional home, although we did use open trusses to facilitate the installation of ductwork and radiant heating coils under the floor.

Here you can see the crew working in the kitchen, adding framing in the attic area. If you look closely, you can see the channels cut to the electrical boxes.

Finishing an ICF Home

Drywall is screwed into plastic strips in the ICF forms, allowing the home to be plastered and finished like a conventional home. There are no ugly, bare concrete walls. The only indication you have from inside that the house is not standard construction are the deep window wells and doorways.

Here's another view of the kitchen, later in construction with the cabinet frames, flooring and lighting in place.

The look and functionality of the home is similar to a standard home, only better. (I may be biased. ;-)) The interior and exterior can be finished in the same way as a conventional home – siding, brick, drywall, paint, carpets, etc. In our case, we chose to use all hard surface flooring on the main floor and acid stained concrete in the basement to maximize the heat transfer from the in floor radiant heating and improve indoor air quality. Our home is certified Wisconsin Green Built and Energy Star compliant.

We utilized no and low-VOC materials and finishes within the home; sustainably harvested hickory and wheat board for our cabinets and shelving; green flooring such as tile, cork and linoleum – I could go on, but you get the idea. About the only thing that is a little tricky is hanging things on the exterior walls, because there are no studs and the stripping is hard to find under the paint and drywall. I use removable adhesive tabs instead.

Do it Yourself ICF Construction

I would not recommend do it yourself ICF construction for the average handy person. It can be done, but you need special equipment and you don't want to screw up. Walls and openings must be well braced to maintain structural integrity. You only get one chance to pour it right and it can’t be adjusted after the fact. Dedicated ICF builders have specialized braces for this purpose, and know how to work with the forms to avoid problems. Also, the cement mix must have just the right consistency. Too loose, and you risk blowing out a wall. Too thick, and you’ll end up with air pockets in the wall because the cement has trouble filling the forms completely.

If you are on an extremely tight budget, and ICF safe room is probably a better choice. A safe room is a small, windowless room built inside the shell of the home or garage or nearby, that is used primarily for emergency shelter.

View inside the basement with windows, framing, plumbing and electrical in place.

Our Experience Living in an ICF Home

The home is very quiet. The noise reduction from the ICF is noticeable to anyone who visits. We've been in the house over 12 years now, and it's holding up extremely well. Several people who came to last year's open house noted that the home didn't look 12 years old.

Our heating and cooling bills are still low, and I would definitely recommend ICF construction.

Our assistant construction crew, playing on the job site while the house was being built.

ICF Recommendations

Our first home was a stick built, our second is ICF. After going through the building process with both, there are a few issues unique to ICF. (These may also apply to other specialized building options.)

Plan for Ventilation

You need plenty of ventilation because the home will be so tight. Don’t count on natural convection (normal heat/cold airflow) to move air around the house. You will need point source ventilation and an HRV or ERV with ICF construction.

Use an ICF Builder

Make sure you get a builder who has worked with ICF before. It is not the same as a stick built home. Windows and doors must be exact – you can't cut a wall and add a stud like you can with stick built.

Get Durable Windows & Sills

Windows and sills must tolerate wider temperature swings and condensation if you use insulating window covers. Make all window sills tile or other water resistant material. Since our home uses passive solar design, large windows are needed. These must be covered at night to avoid excess heat loss. Covered windows + tight home = condensation.

I’ve taken to applying a layer of insulating window plastic on the inside of the north windows at the beginning of the heating season. (In retrospect, we should have probably upgraded to the triple pane windows with argon fill on the north side of the house, instead of a good quality double pane.) Our window frames are vinyl to reduce heat loss from the home and prevent rot.

Here are two stacks of the v-buck window frames used with the ICF forms. Note the thickness of the frames to match the thickness of the ICF walls.

More on Green Building

Learn more about green home building and sustainable living on the Green Home page. My husband and I are also working on a book detailing our building experience and offering guidance for building a “lifetime home”. If you'd like to receive information on when the book is available or have any questions/concerns you'd like addressed, leave a comment below.

You may also find useful:

- Aging in Place -Making Your Home Livable for a Lifetime

- Solar Water Heating Basics

- Best Ways to Keep Your House Warm – New Construction and Remodeling Tips

Originally published in 2012, updated in 2018.

The post ICF Construction – What You Need to Know About an ICF Home appeared first on Common Sense Home.

This Article Was Originally Posted at commonsensehome.com Read The Original Article HereSee More Here: ICF Construction – What You Need to Know About an ICF Home

No comments:

Post a Comment